Our Continuous Improvement team wishes to update you on the progress of the 5S project in Longueuil.

We completed the 5S on the PRIMA 12 (cutting and bending steel), the SCHNELL 26 (cutting and bending steel) and the Coil 18 (automatic bending).

Work is now being done on the cutting machines (Shear).

Our goal is to complete the 5S project in mid-April at the ARMABEC plant. Audits are conducted on a daily basis to maintain the same level of organization and cleanliness. They will be carried out on a continuous basis.

Several completed actions had a significant impact on the organization of production activities and on the operators’ work environment as shown in the illustrations below. In addition, some of these improvements reduce the risk of injuries (order and cleanliness) and make it easier for everyone to move around the plant.

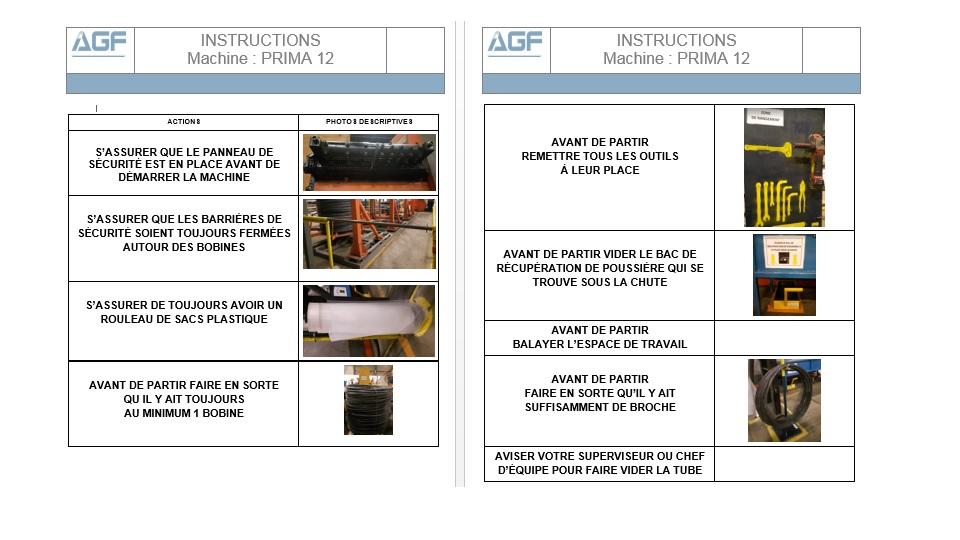

Tool storage panel, with imprint, which avoids tool losses and wasted time searching tools. Result - Time saving: 15 minutes per shift. |

A storage location for cleaning items nearby, to encourage daily cleaning. |

Indications to keep the workstation clean. Result – Cleaner workspace. |

A steel wire dispenser was added to the work console, to save time on the wire search. Result - Time saving: 15 minutes per shift. |

Storage areas identified to save time in researching projects. Result – Saves storage space. |

Reminders of work standards displayed on the console, to maximize operational time and limit movement. |

El equipo del departamento de mejora continua desea informarles sobre los avances del proyecto 5S en Longueuil.

Habíamos terminado las 5S relativas a la máquina PRIMA 12 y a la SCHNELL 26 y la COIL 18.

Por el momento, se está trabajando en las máquinas de corte (Shear).

Nuestro objetivo es terminar el proyecto 5S a mediados de abril para la fábrica ARMABEC. Se realizan auditorías diariamente sin parar con el fin de mantener el mismo nivel de organización y de pulcritud.

Se realizaron acciones de mejoras simples, las cuales tuvieron un impacto importante en la organización de la producción y en el ambiente de los operadores.